Reflecting on the 2025 Viwinco Summer Internship Program

As summer 2025 comes to a close, we’re proud to celebrate the success of this year’s Viwinco Summer Internship Program. This year we welcomed nine students from seven universities and across two different countries, who brought energy, insight, and dedication to meaningful projects across the organization.

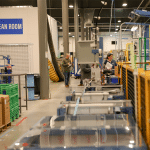

Over the past 10 weeks, our interns partnered with mentors on initiatives supporting lean manufacturing, process improvement, and cross-departmental collaboration. They applied classroom knowledge to real-world challenges making measurable contributions to our continuous improvement goals.

Each intern was assigned to a different department, immersing themselves in projects aligned with their field of study. Their contributions had a notable impact on our operations:

Tyler Bennis – Operations (Glass)

Supported Operations by driving process efficiency and contributing to strategic projects tied to Viwinco’s $200M growth target and LEAN transformation; with a focus on improving Remake On-Time Delivery and Glass Yield.

Chris Lewis – Engineering

Contributed to a wide range of impactful projects supporting Viwinco’s building transformation. Key initiatives included equipment block verification for the facility move, designing custom carts, creating a Yamazumi template, and conducting time studies. Collaborating with both Engineering and Production teams, the intern applied technical and communication skills to solve real-world challenges—gaining valuable hands-on experience and advancing his professional development.

Lucas Wiedmann – Continuous Improvement

Partnered with the CI team to develop standard work packages for the Picture/Slider and Line 1 areas and helped implement 5S standards. He also conducted time studies on the 650/Patio Door line to support efficiency improvements. In the final weeks, he contributed to a screen production project for Lines 2 and 3—identifying issues through time studies, proposing a new layout, and helping implement the changes, which have already improved efficiency.

Zack Weinstein – Reliability & Maintenance

Assisted with maintenance tasks and equipment breakdowns, created documentation for preventative maintenance procedures, and worked on optimizing New Glass Shop processes to improve insulated glass unit quality.

Joe Carello – Quality

Supported quality and process improvements by organizing the quality test and quality reject areas using 5S, creating training materials – like one point lessons for Viwinco labels, and verifying plant layouts for future equipment. Additional contributions included a screen damage prevention study, assisting with nonconforming material systems, and collecting clean room humidity data to support key process problem solving initiatives.

Michael Dougherty – Engineering

Designed new carts for the screens department, which involved conceptualization, sketching, and 3D modeling. He also modeled and 3D printed an add-on for the drill press on the hopper line to support future state processes. In addition, he conducted time studies to analyze and create process steps for operators on the floor.

Steve Tello – Supply Chain

Provided valuable insight into both the window industry and day-to-day operations behind the scenes. Key contributions included conducting time studies, assisting with a new rack labeling system, and supporting the material delivery project. We’re excited to have Steve continue with us into the fall as a Supply Chain Intern while pursuing his studies!

Will Culbert – Research and Development

Created Fusion CAD models and drawings for our products, CNC machining a harp cart base for our New Glass Shop, verifying the reliability of one of our glazing bead punches, and designing and testing some new window buck dollies.

Abdullah AlSabban – Operations (Vinyl)

Assisted management with everyday tasks and responsibilities. Worked on one point lessons mainly for Picture Window Slider but for other lines as well, focusing on setting a clear standard for operators to maintain quality and workflow.

Throughout the summer, weekly check-ins with HR Business Partner Elena Kollar kept interns aligned with their goals, encouraged collaboration, and provided valuable guidance. The program culminated in final presentations, where each intern showcased their projects and shared key insights with our leadership team—a true testament to their growth, hard work, and the meaningful impact they made at Viwinco

We’re also celebrating a full-circle success story—this summer, we welcomed former intern Tyler Blagden back to Viwinco as a full-time R&D Engineer. After spending two summers with us as an intern, Tyler has officially joined our Research & Development team, and we look forward to seeing his continued growth and contributions.

Looking ahead, we’re eager to keep connecting with future students and offering hands-on experiences that bridge classroom learning and real-world application. The 2025 Viwinco Summer Internship Program has been a great success, and we can’t wait to welcome more passionate students in the years ahead. Recruitment for our 2026 interns begins in February—those interested can contact Elena Kollar at ekollar@viwinco.com or visit our Indeed page for postings at https://www.indeed.com/cmp/Viwinco/jobs.

Want to hear directly from our interns? Check out our Intern Spotlight videos featuring Chris, Steve, and Zack as they share their favorite moments, projects, and lessons from the program!