Safety Initiatives & Programs at Viwinco

Why is Safety so Important?

Health and safety are key factors for all industries. Maintaining safety standards promotes the wellness of all employers and their employees. With the trying times of 2020, health and safety are extremely prevalent, now more than ever. There have been several major procedural updates and exciting hires since the start of the pandemic. The future of safety at Viwinco looks bright, with many new programs and incentives in the works. Here is a look at how Viwinco is improving safety!

COVID Safety Procedure Updates for 2021 and Beyond

At the start of the pandemic, there was a mandatory, two-week company shutdown which allowed management to plan additional safety measures to be implemented upon employee return. We sat down with our Human Resources Director, Zach Kuhn, who provided an in-depth overview of Covid-19 procedures.

“At the beginning of the pandemic, we instituted as many opportunities for social distancing while ensuring that the building of our product did not cease. We also ramped up our sanitation teams internally and opted for a company-wide mask mandate. An opportunity for training was provided to all employees of personal hygiene habits such as the time needed to wash hands to prevent the spread of disease.”

Once on-site, employees were required to wear masks at all times while on company property. Pre-shift temperature screenings, hand sanitizer, and masks were given at the front desk while employees who showed symptoms received Covid-19 tests.

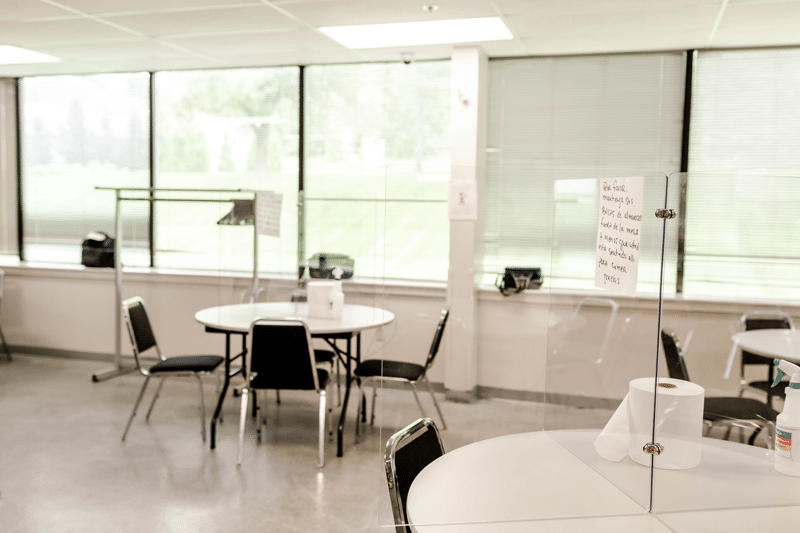

As the vaccine became more readily available, Viwinco provided on-site vaccination centers where 75 employees thus far have been vaccinated. These vaccination centers were set up in our R&D Training Center, readily available for any employee wanting the vaccination. We continue to follow OSHA and the CDC’s guidance to ensure we maintain a safe work environment for our employees.

Incentivizing Safe Practices

After rebranding our merchandise to incorporate the new Viwinco logo, we came up with creative new ways to incentivize safety among our employees. Our H.R. department worked with our I.T. Department to create an online ticket system where employees could identify safety concerns they thought needed improvement within the entire company. This was incentivized by rewarding each employee who submitted a suggestion, a newly branded Viwinco sweatshirt if the goal was met. Three-hundred and fifty active safety suggestions were submitted and were used to analyze current safety practices. Some of these safety practices have already been implemented or are in the process of being modified.

New Roles and Big Ideas

Recently a new role was created here at Viwinco. This role is meant for someone who is zealous about identifying safety, health and environmental risks within our company while developing and implementing policies that would be used to improve the overall safety of our company. The candidate was Sharon Flory, who came to Viwinco with a passion for improving workplace safety and implementing safety initiatives, making her the perfect person for the job.

Sharon, a retired firefighter, has held many safety-related positions which provided her with the skills necessary for this new position. Sharon previously worked as a part of a private response clean-up team of hazardous materials and a safety compliance team member working for a company out of both Jersey and Harrisburg. Additionally, she worked six-years as the Environmental, Safety and Health Coordinator at a chemical company in Leesport and started her own company prior to joining the Viwinco family as the Environmental, Health and Safety Manager. Some of Sharon’s current accomplishments and future plans for Viwinco are as follows.

OSHA Outreach Training Program

The Occupational Safety and Health Administration (OSHA)—a regulatory agency within the United States Department of Labor—was originally designed for federal visitorial inspections and examinations of workplaces. One of the main goals of OSHA is to ensure safe and healthy working conditions in the workplace. This is made possible by establishing and enforcing standards by providing training, outreach, education and assistance in the workplace.

Sharon, who is also a certified OSHA Outreach Trainer, has implemented several OSHA initiatives at Viwinco. One of these initiatives is the OSHA 10-hour general industry certification program during new employee onboarding. This program trains entry-level employees to recognize, avoid, abate, and prevent safety and health hazards. Upon completion of onboarding, all new employees will receive official OSHA certification cards on-site from the U.S. Department of Labor.

“The OSHA Outreach Program brings a standard level of knowledge to all employees who complete the program.” Says Sharon.

Within the next month, Sharon plans to implement the OSHA 30-hour course that will provide management with certification of general worksite safety and extensive knowledge of avoiding common hazards, understanding workers’ rights, and employer responsibilities. Like the OSHA 10-hour program, completing the 30-hour course will result in certification cards given on-site to management personnel.

Plans for the Future

One of Sharon’s short-term goals include, reducing Viwinco’s Days Away Restricted or Transferred (DART) rate. This rate determines how safe a business has been within a calendar year and monitors injuries in high-risk industries. The DART rate is calculated by taking the number of OSHA recordable injuries and illnesses that resulted in days away/restricted/transferred multiplied by 200,000 (100 employees working 40 hours a week for 50 weeks during a calendar year). This number is then divided by the total number of hours all employees worked. The industry standards DART rate is 4.8, where Sharon’s overall goal is to have a DART rate of 4, below the industry standards. Currently, the DART rate has been reduced by 43% using Job Safety Analyses.

Another short-term goal, which is currently in progress, is establishing an entire written health and safety program. This program overviews lock-out-tag-out procedures and installs an audit program. Health fairs and health education are also in the works to motivate employees to stay healthy, which improves the long-term health of all employees. Finally, she will build a safety committee by the end of this year, providing a 10% state-certified insurance discount.

Sharon has many big goals that she plans to accomplish in the future. One of the most significant goal is the implementation of the Voluntary Protection Program (VPP). This program recognizes employers and workers in the private industry who have implemented effective safety and health management systems and maintain injury and illness rates below the National Bureau of Labor Statistics averages for their respective industries. The VPP will promote adequate worksite-based safety and health. Sharon hopes to restructure current workplace safety management systems and build a complete safety program within 3-5 years while earning the VPP status in 5-8 years.

It is safe to say that we are thrilled and appreciative to have Sharon as a part of the team and expect significant changes ahead!

What to Expect from Our New and Improved Onboarding Process

Viwinco recently introduced changes to our onboarding process. We have shifted the onboarding process from physical paperwork to allowing new employees to complete everything online. There is also a 2-day on-site new hire training schedule. On day one, new workers receive fundamental plant training, HR and safety training, and a lean manufacturing overview. On the final day, new workers receive: an introduction of our product, learn how to safely move materials through the plant and training on tool usage. This training is then expanded to job-specific training where new hires will be taught how to succeed in their new roles.

From a safety perspective, employees are now learning what to expect from Viwinco and having the opportunity to talk to senior staff about the future they have with us.

Sharon explains, “New employees are made to feel welcome by walking into a family-like setting rather than a regular workplace. They also receive hands-on experience of working with the equipment as a way to teach the basics, so they feel comfortable when starting their positions. By revamping the onboarding process, our turnover rate has vastly improved.”

Enhancing the Safety Measures Required on the Plant Floor and the On-Site Construction Work Zone

The enhanced safety measures being implemented are stricter Personal Protective Equipment (PPE), while on the plant floor or while near/on the construction work zone of our new glass facility. In order to determine Job Safety Analysis (JSA)—a tool that can be used to define and control hazards associated with a certain process, job or procedure—we must break down every task into ten details, so every employee is protected no matter what. All employees must wear composite-toed shoes and safety glasses while in the plant. Viwinco reimburses every employee $100 towards safety shoes that were purchased out of pocket. Employees have up to a year to show proof of purchase to receive any reimbursement. Access will be prohibited to the plant if the correct PPEs are not worn. Hard hats and safety glasses must be worn in any construction zone, especially at the site of the new glass facility currently in progress next to the Viwinco R&D building and Training facility. The task at hand determines what kind of PPE is needed.

Sharon explains, “When the employee could possibly be exposed to cuts —such as a vinyl worker engaged with glass—different types of gloves, from a cut sleeve to A9 gloves, can be used and are determined by the level of engagement. The risk needs to be evaluated, so each employee has the correct equipment to perform their jobs safely. I would like to establish a PPE program from the ground up to improve the wellbeing of Viwinco and their employees.”

The safety initiatives that have been implemented are already having a huge impact on the company. The company’s safety has had a positive change and overall company rapport is at an all-time high. Having Sharon onboard to manage and answer any safety concerns gives our employees the confidence to reach out to upper management with their ideas, suggestions, and comments knowing that they will be heard. We are excited to see what Sharon does in the future!