Impact Windows: Protection Against Hurricanes

Hurricanes are among the most devastating weather events. Capable of over 180 mph wind speeds and producing severe flooding, hurricanes wreak havoc in the coastal areas of the Atlantic throughout hurricane season (June 1st – November 30th). This year, forecasters at the National Oceanic and Atmospheric Administration (NOAA) are predicting the 2022 hurricane season to have ‘above average’ hurricane activity. This would make 2022 the seventh consecutive above-average hurricane season. Not only are hurricanes occurring more frequently, but according to data, hurricanes have been increasing in severity over the past four decades. Because of this, it is crucial to identify ways to protect your home in the event of a hurricane. One of the most pertinent is the installation of impact windows.

How are Impact Windows Made?

A few different components make up the impact-resistant glass package. For the Viwinco OceanView impact-resistant products, the process begins in the glass shop. The glass lites are cut to size and sent to the tempering and laminating lines respectively. When creating tempered glass, the glass is sent through the tempering oven where it is subject to a series of heat and cooling cycles that vary depending on the glass thickness. Once completed, the tempered glass is sent to the Erdman IGU processing line to wait for the laminated glass.

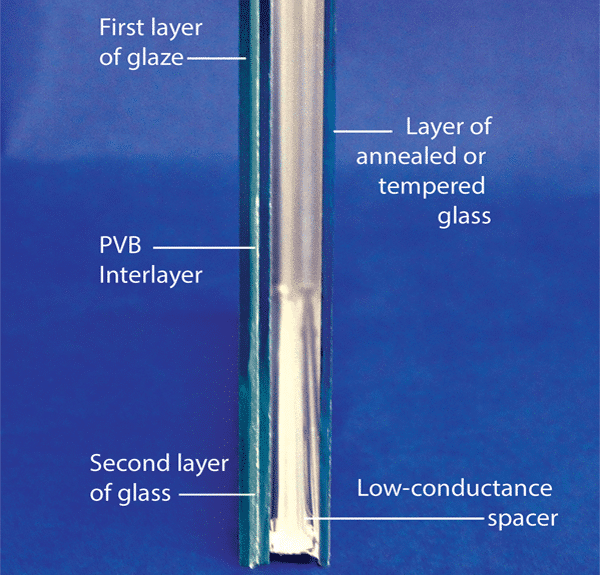

The laminated glass starts in the clean room, where the PVB sheet is cut to size to match the two clear glass lites. The operators then sandwich the three pieces together and feed them into an oven where it is fused together. This adheres the glass to the PVB but results in an opaque glass sheet. The laminated glass is then placed on a cart and loaded into the autoclave where it is subjected to a cycle of heat and pressure. Once completed, the laminated glass is brought to the start of the Erdman line, where it is paired up with the tempered glass lite, and processed into an Insulated Glass Unit (IGU).

The two glass lites are loaded onto the Erdman line where they are lined up and a spacer is applied around the perimeter of the two lites creating an air gap between the two lites. The air gap is then filled with argon gas to enhance thermal performance and a fourth corner seal is applied over the hole to seal the argon inside. Once fully sealed, the impact IGUs are sent to the final assembly area where they are placed into the vinyl sashes/frames and prepped for delivery.

This process will change drastically, following the completion of our state-of-the-art glass facility which includes new equipment and entirely new processes.

Impact windows: Laminated, Tempered and Annealed Glass

To understand the benefits of impact windows, you first need to know the different types of glass used in windows and doors. Annealed glass is your standard untreated sheet of glass. One characteristic of annealed glass is that it creates jagged shards when it breaks, which can cause lacerations if improperly handled. Tempered glass—also referred to as safety glass—is annealed glass that has been heat strengthened. Not only is it 4-5 times stronger than annealed glass, but when tempered glass is broken, it no longer breaks into sharp pieces. It now shatters into tiny cubes referred to as “dice” which are much safer than broken annealed glass. Laminated glass is the most complex of the three. It is a layered glass sheet with a Polyvinyl Butyral (PVB) interlayer. Laminated glass is very resilient and is designed to protect the building envelope even when struck by windborne debris.

How do Impact Windows Protect your Home from Hurricanes?

Impact windows are designed to reduce the likelihood of your home being breached by windborne debris in a powerful storm such as a hurricane. This is important because if your windows are breached and the building envelope is compromised, the combination of water and air pressure can rapidly build up within the building envelope. With no way to equalize the pressure, something will ultimately give within your house. This can be additional windows, doors, the roof or can cause walls to give out entirely causing the house to collapse. Should your impact windows be struck by windborne debris in a hurricane, the exterior tempered glass may break, and the laminated glass might crack, but it should remain intact to prevent the pressure buildup.

Impact Products and the New Viwinco Glass Facility

As we get closer to the completion off the new glass facility, we are beginning to test some of the new machinery that will be used to manufacture our OceanView impact window and door glass units. Two of the most innovative pieces of equipment we purchased to produce impact-resistant products include a new tempering oven by Glaston and a glass laminating line by Bürkle.

Glaston FC Series Tempering Furnace

The Glaston FC Series tempering furnace combines the next generation of tempering machinery with highly sophisticated software to manage the production of tempered glass lites. A historically complex process, glass tempering is a highly variable process that includes formulas that will change by glass batch. The furnace’s intelligent software provides enhanced control over the tempering process to ensure accuracy with the tempering formulas. The furnace also includes Active Edge Control to minimize edge lift as the heated glass moves along the rollers. The Glaston furnace will ensure high-quality tempered glass is consistently being produced.

Bürkle Easy-Lam IFL — Inline Glass Panel Lamination

The Bürkle Easy-Lam IFL laminating line will entirely revolutionize the way we manufacture our impact glass and will significantly reduce the cycle time per glass unit. Traditionally, the laminated glass is run through a thermal oven where the PVB is fused with the glass lites. It is then subjected to a lengthy heat and pressure cycle in the autoclave. Not only does this create a bottleneck in production, but if glass needs to be remade, the turnaround time for that unit can be lengthy. The Bürkle line does away with the traditional autoclave process in favor of three heavy presses to produce the laminated lites. The first press is a heated vacuum press to remove the air from between the different layers. The second press applies heat and pressure required to create the laminated glass. The final step is a cooling press to remove the heat and apply safe handling as the units are removed from the line. In total, the cycle time is approximately 12-minutes, a significant improvement over the previous cycle time in the autoclave of over 3-hours. Along with the impressive machinery comes intelligent software to assist with glass alignment and yield operation. The Bürkle line will be monumental as we continue to support impact product growth in the southern and coastal areas.

Misconceptions About Window Safety During Hurricanes

There are many ways to protect your home when it comes to hurricanes, however, there are also some dangerous misconceptions that can put you and your home at risk. One of the most dangerous is leaving your windows slightly open to equalize the pressure in your house. Not only will this allow water to get inside, but it can also allow pressure to build up quicker than it can dissipate, possibly resulting in severe structural damage. Another common danger is applying tape to your windows to prevent glass breakage. This of course creates a serious hazard if you have windows with annealed glass as it will allow large glass shards to become windborne projectiles if the windows are broken.

Benefits of Installing Impact Windows

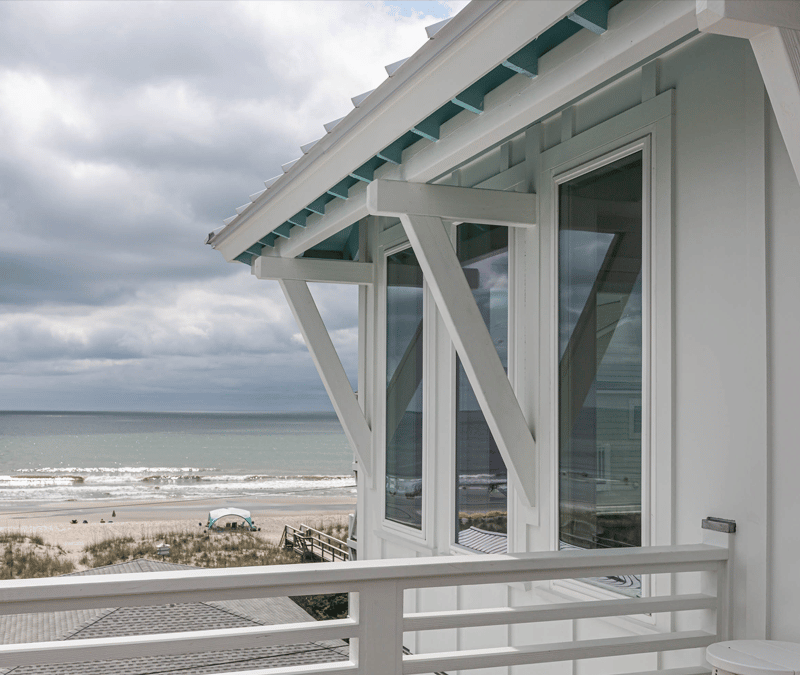

There are several reasons why it is beneficial to install impact windows, the most prominent being added safety in the event of a powerful storm. Still there are additional reasons you should consider impact windows for your home. Our OceanView impact-resistant product line offers enhanced thermal performance. Viwinco OceanView products contain a combination of Low-E and laminated glass which can significantly reduce the amount of ultraviolet light (heat) that enters the home, leading to reductions in your energy bill. Impact windows also enhance the look of your house, unlike bulky shutter systems. They also don’t require setup to be functional. The laminated lites greatly decrease sound transmission, which can be ideal if you live in a noisy area. Impact windows can also be a deterrent for forced entry and have been installed in banks and schools. One of the most important benefits of impact windows is the peace of mind, knowing that your home and belongings are safe in a hurricane.

What Now?

Hurricanes are here to stay and according to the data, they’re only becoming stronger. The installation of impact windows not only provides year-round benefits, but also provides the protection you need during a hurricane and peace of mind. If you are interested in installing impact windows in your home, check out the Viwinco Buyer’s Guide which provides an overview of the window buying process. If you are looking to find a Viwinco distributor or installer, check out our Where to Buy page to locate a distributor near you!