Manufacturing Automation Trends in the Fenestration Industry

Over the last decade we have become increasingly reliant on technology. We carry smartphones in our pockets, integrate intelligent software applications with our vehicles, and are always connected to the internet — so it is only natural that technology has made its way into the home.

Today’s “smart homes” have computerized heating and cooling systems, advanced home security, virtual assistants showcasing the latest developments in artificial intelligence and interconnected lighting systems all controllable through a centralized hub—or in many cases—through your smartphone. The rising trend in smart home technology has led to an influx of impressive manufacturing automation processes throughout the fenestration industry.

Manufacturing Automation in Window and Door Production

The window manufacturing process is often complicated, lengthy and riddled with opportunity for human error. In an industry where your product is reliant on accuracy, speed and consistency, automated machinery is crucial for ensuring your product meets the needs of the customer and industry standards. Our manufacturing plant here at Viwinco is home to many state-of-the-art machines that help to automate the manufacturing process.

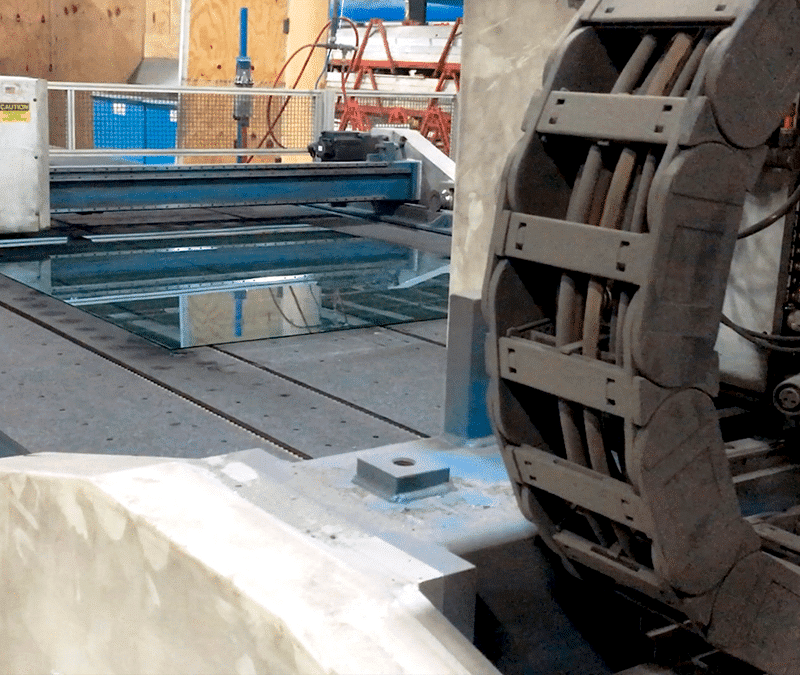

GED 6000 Series Glass Cutter

The window/ patio door manufacturing process really begins with the glass cutting process. Utilizing state-of-the-art scoring and an intelligent yield optimization algorithm, the 6000 Series guarantees precision-cut glass while reducing scrap. While cutting the glass panes, the cutter grinds and smoothens the edges of the glass lites. This results in a smooth IGU (Insulated Glass Unit) seal.

Joseph Machine Company — H4W Horizontal Vinyl Welder

Whether you are welding sash or a frame, there is a lot of room for error. If your weld is not strong enough your window can fall apart or not seal properly. If you weld too much, your window may not operate properly or fit the specifications the customer asked for. The H4W allows for the welding of all four corners simultaneously for the perfect and consistent weld at each corner. The H4W also allows for four sashes (of the same size) to be welded at the same time to help speed up the manufacturing process.

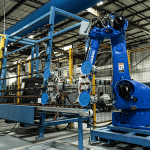

GED Roboclean®

The Roboclean® is the latest in robotic Vinyl cleaning technology. When a sash or aframe comes out of the welder, there is a messy residue around where the four corners meet. Utilizing two robotic arms equipped with saws and skiving knives, the Roboclean is able to finely clean two vinyl corners simultaneously. The Roboclean’s infinite axis accessibility results in consistent, repeatable movements at angles previously unattainable.

Automated Glass Tinting

When using an automated tinting product like Smart Tint®, you can easily repurpose your transparent glass unit by applying an adhesive film that can turn it opaque with the touch of a button. This can be a great improvement to any office space or area where you sometimes need privacy but do not want the area to feel isolated. In addition to Smart Tint’s® privacy benefits, they also state that their film blocks out 98% of harmful UV radiation and performs well as a projector surface once the glass is opaque.

Autoslide® Window and Door Automation

Autoslide offers an easy-to-install solution for transforming your standard patio door or slider window unit to an automated system. The Autoslide® mechanism comes in a number of configurations that can fully automate doors of any size. Once programmed, the Autoslide can be controlled by touch pad, remote control, or motion sensor, providing a seamless home integration. Being designed for both domestic and light commercial settings, the Autoslide® is the go-to for door automation.

Blind Automation

Blinds have always been a great way to control the amount of light you let into your home while contributing to the home’s overall design and appeal. Intigral offers a solution with their motorized blinds line where you can embed a sleek venetian blind system inside the IGU. The motorized blinds come in two configurations. One powered by a rechargeable battery, and another that plugs directly into a power source. The blinds are controllable with a wall-mounted push button or remote control, once installed.

Another option for blind automation is the Hunter Douglas’ PowerView® Motorization. With the PowerView® you have the ability to program blinds to open and close with the tap of a button. The blinds are fixed at the top of the windows and come in a variety of styles. The PowerView® is programmable, allowing users to schedule exact times when they’d like for their blinds to open and close.

Benefits of Manufacturing Automation in Windows and Doors

There are a number of benefits that come with automation in the fenestration industry. One of the most pertinent is the ease of use that comes with the automation. If you or a loved one is living with a disability, having to open a patio door or a window can be difficult and in some cases impossible. With the installation of some of the products listed above, navigating your home could become much easier.

The automated products in the fenestration industry listed above are just the tip of the iceberg. Manufacturing automation will be a main focal point during 2018 “GlassBuild” and “Glasstec” .